ENGINEERING

PIPING ENGINEERING-STRUCTURAL ENGINEERING-DOCUMENT CONTROL SUPPORT

Here are some of the highlights of our on-staff engineering team and their capabilities:

- A dedicated document control group and controlled receipt and distribution of contract documents system uses bar codes for optimum data and filing accuracy.

- An electronic file management system accessible to all shop and office personnel gives us instant access to client specifications and related information and drawings, helping ensure ongoing accuracy of the project.

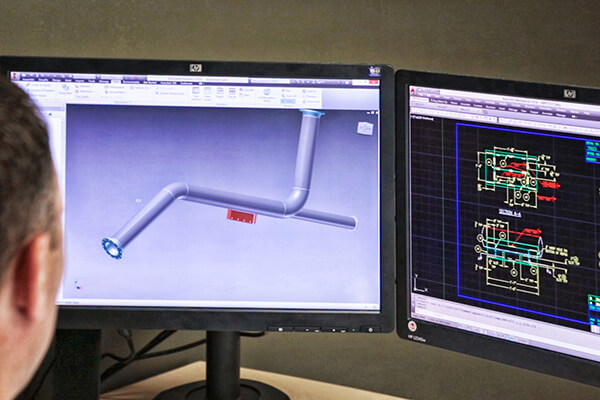

- EDI and 3D capabilities using Spoolgen mean automated material takeoff and reduced delay. 2D drawings are handled with I-Sketch.

- An electronic library of documents related to the work being performed throughout the company, including job specs, drawings, codes, etc., so there are no gray areas when it comes to accurate information. Our “key document” process puts all information needed to fabricate the spool to its project and code requirements on the shop drawings; this functions as a Quality Control Traveler document to ensure that everyone is “on the same page.” Document control packages include spool drawing, iso drawing, material test reports, weld map/QA spool drawing, PMI reports, heat treat charts, paint reports, hardness reports, RT reports, PT/MT reports.

- Fabrication Progress Reports provide exact and detailed status of each spool through each step of its fabrication, from isometric receipt right through shipment. This information is also readily available to customers.

- Our Isometric Flow Chart controls the accurate fabrication and flow of spools through engineering and the shop. This multi-step process includes a number of precision checkpoints along the way, with automatic flagging and detailing of every spool requirement involved in the fabrication.

- Pressure Vessel design using Codeware Compress software and design/detailing using AutoCAD and Inventor.